How Lenses Are Made - Part 3

Surfacing

Once we receive your order, the journey to a finished pair of glasses begins in our surfacing department. Here is where the prescription is cut into the lenses.

From Lens Blank to Prescription Lens

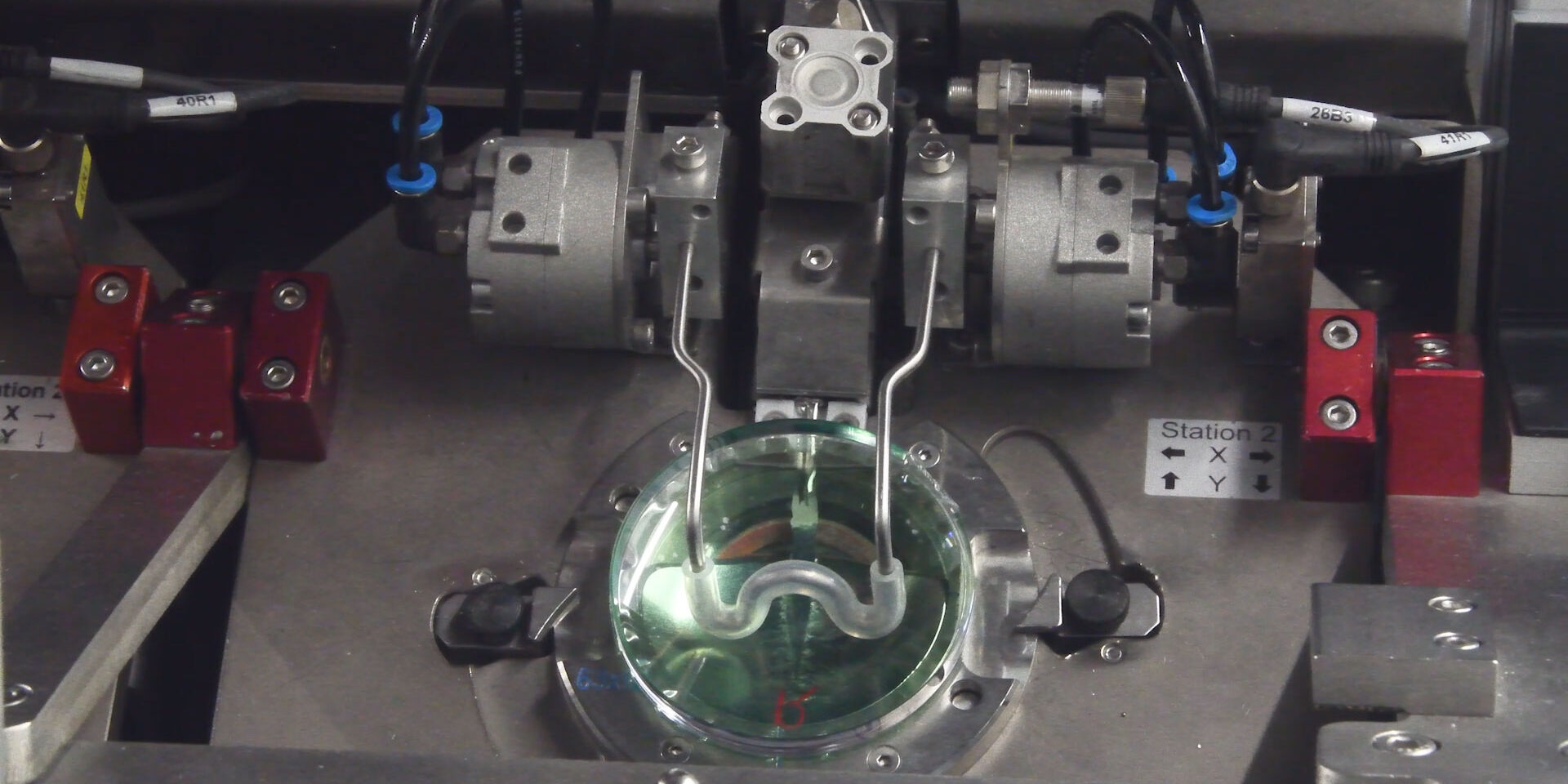

We start with a lens blank, attaching it to a fixture with a medium like wax or alloy. This allows our machines to hold the blank securely as it moves through the process.

Unlike the glass molds we make in another part of our lab, surfacing lens blanks doesn’t require diamond tools because these blanks are made from softer materials like polycarbonate or plastic.

Cutting the Prescription

The generator then cuts the prescription directly into the back of the lens. At this stage, the lenses look frosted as they're covered with fine scratches. To bring them to optical clarity, we put them through polishing where abrasive pads and polishing compounds smooth the surface until the lens is crystal clear.

After polishing, the lens is de-blocked and prepared for its protective coatings.

Protective Coatings

After polishing, the back surface of the lens is softer and more vulnerable. To ensure durability, every lens goes through a hard-coating process where a clear lacquer is applied for long-lasting protection.