How Lenses Are Made - Part 2

Lens Casting

Before you process a lens for a prescription, you need to start with a lens blank. Here’s how we make one from start to finish.

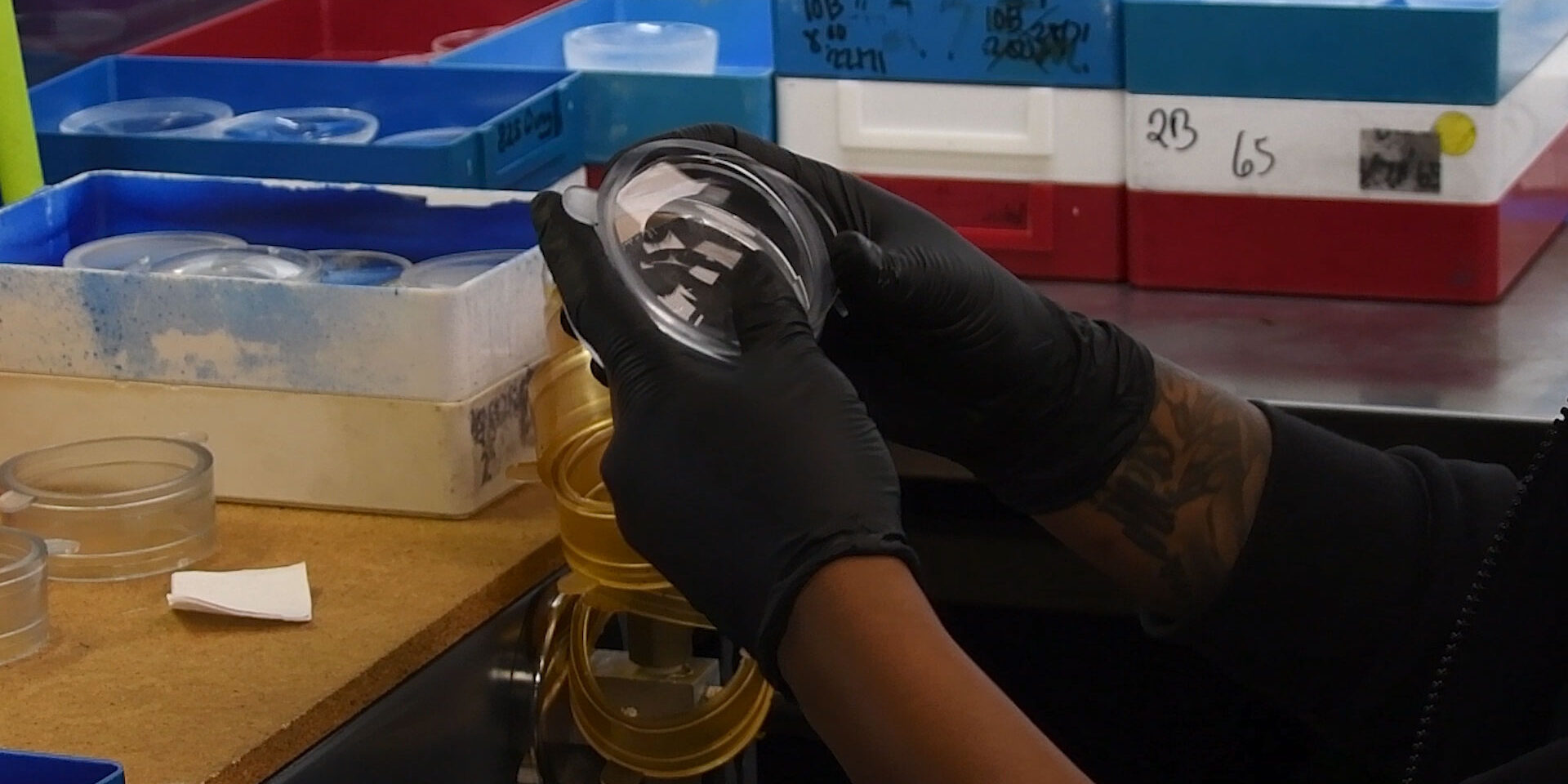

Step One: Preparing the Mold

When an order comes in, if we don’t already have the lens blank in stock, we manufacture it in-house. The process begins with a front mold and a back mold, which are placed inside a rubber gasket. This gasket, along with a giant rubber band, hold the molds securely in place.

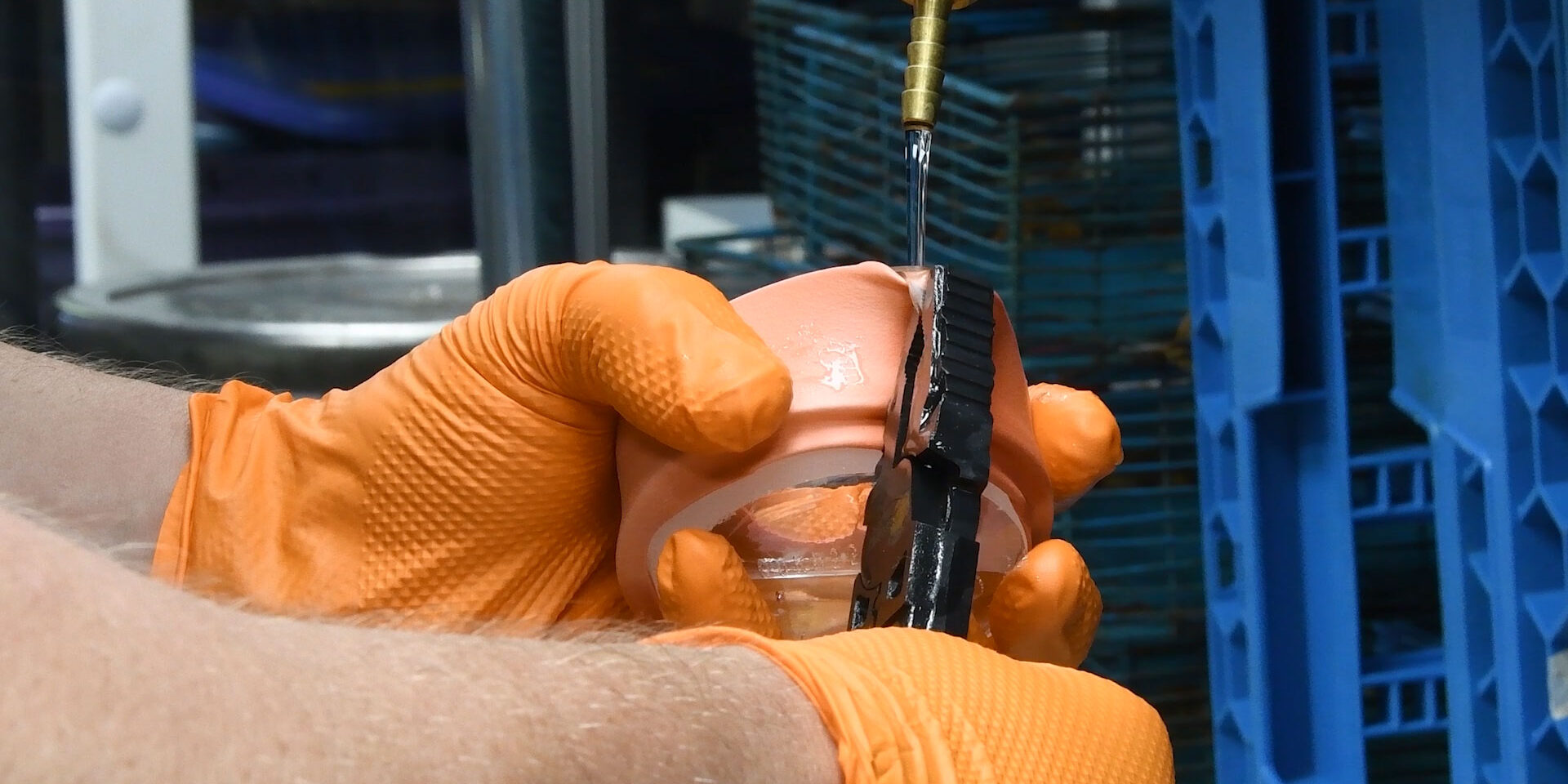

Step Two: Pouring the Monomer

Next, we pour the monomer material between the molds. This mixture is made of two parts:

- The ophthalmic material, a clear syrupy liquid

- The initiator, which triggers a controlled chemical reaction

When combined, these components generate heat and begin forming the solid lens material.

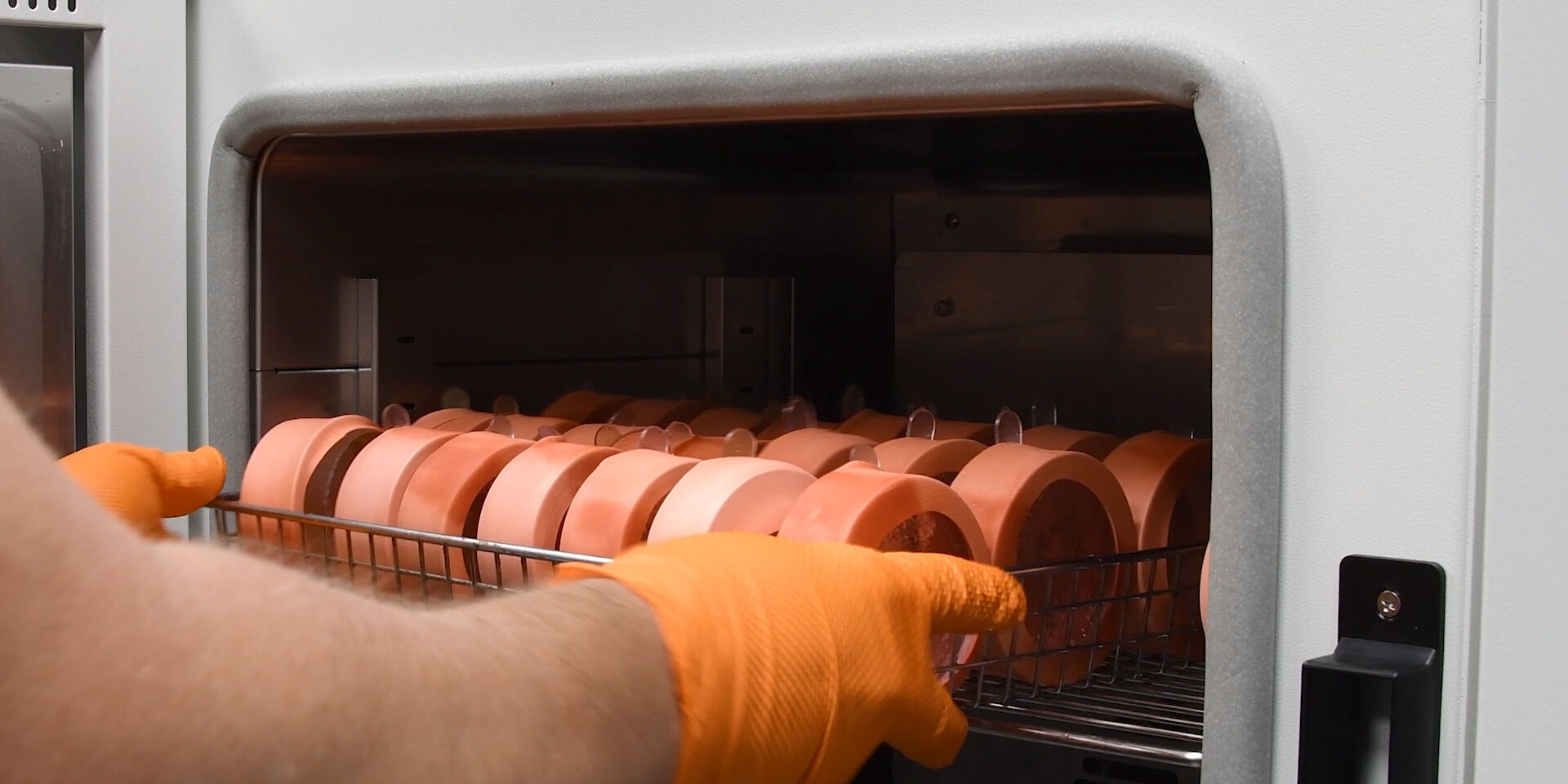

Step Three: Controlled Curing

The filled molds are placed into an oven for a carefully monitored 22-hour curing process. This slow and even heating ensures stability - preventing cracks and flaws that could compromise the final product. By controlling the heat over time, we create a strong, reliable blank that can later be shaped into prescription lenses.

Step Four: Quality Check

After curing, the lenses are removed from the molds in a process called de-blocking. Each blank then undergoes a rigorous quality check. We inspect the surface for scratches, bubbles or any imperfections that could affect clarity. Only lenses that pass this inspection move forward.

Step Five: Ready for the Lab

Once approved, the finished lens blanks are labeled, boxed and shipped to our lab where they’ll be surfaced and shaped into custom prescription lenses.