How Lenses Are Made - Part 5

Edging (Glazing)

Once the prescription has been surfaced and coated, the next step is edging: shaping the lenses so they fit perfectly into your patient's chosen frames.

Starting with the Prescription

For progressives and bifocals, lenses always go through surfacing so we can precisely build the prescription. For single-vision lenses, we have two options:

- Surfaced lenses – cut from semi-finished blanks in our lab

- Finished lenses – purchased pre-made with prescription powers, then aligned and edged in-house for faster turnaround

Regardless of the path, every job begins with dotting. This process verifies the prescription in the lens and places axis marks so everything lines up correctly during edging. At Chadwick, we use the A&R Pro Mapper, which scans the lens with cameras and lasers, compares it to the digital file and prints precise markings for alignment.

Cutting Lenses to Shape

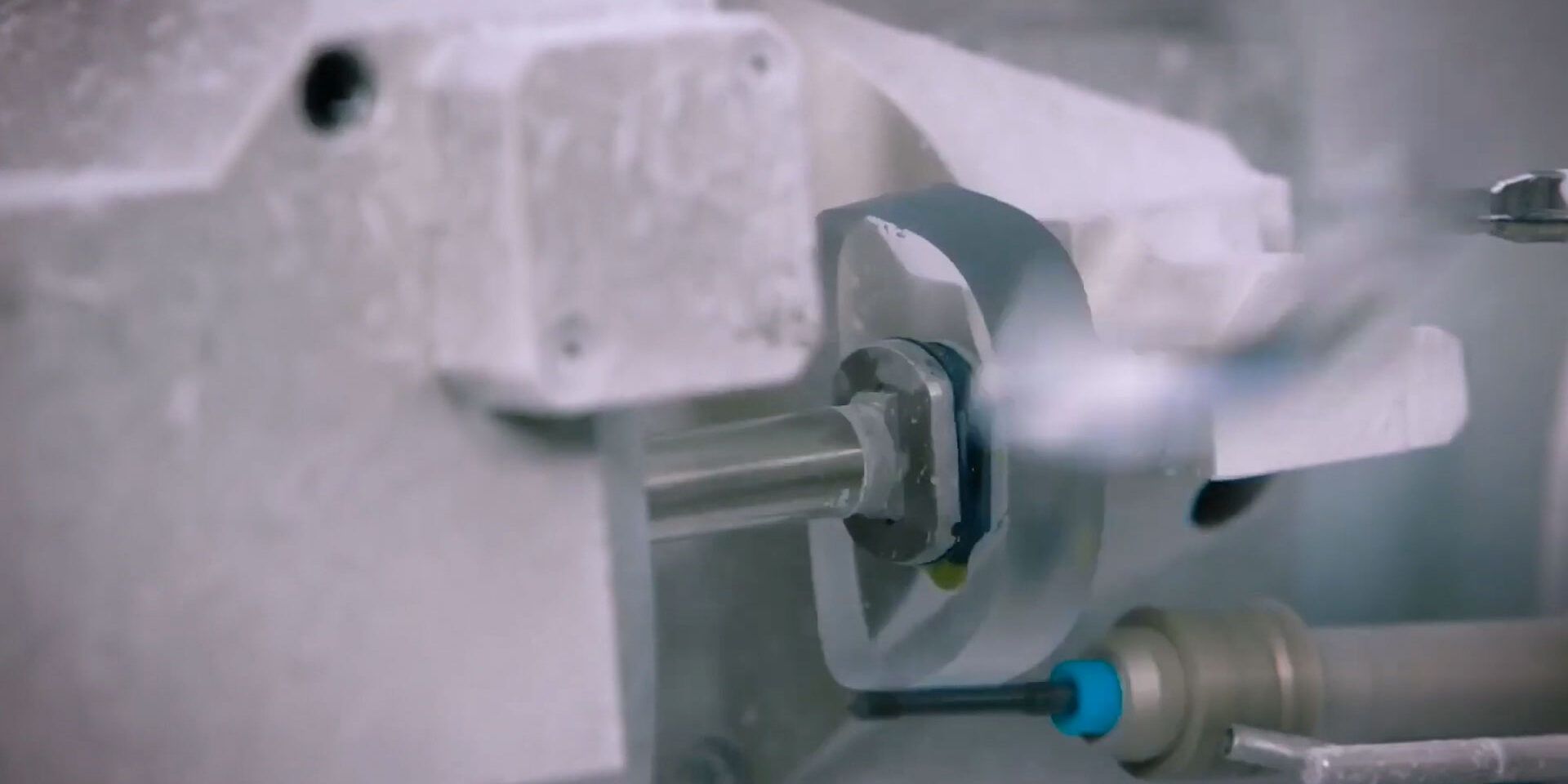

Once dotted and paired with the frame, lenses move to our edging department where they’re cut from circular blanks into the exact shape of the frame.

We use two main approaches:

- Blocked edging – A block is applied to the lens, holding it securely in the machine while it’s cut.

- No-block edging – With our advanced MEI edger, suction cups hold the lens in place, eliminating the need for a block.

Our Edging Machines

At Chadwick, we use both 6E edgers and MEI models:

- 6E Edgers – Classic three-axis machines. They cut lenses to size and handle standard bevels like Hide-A-Bevels and grooved edges.

- MEI EZ-Fit & NBL Edgers – Advanced five-axis machines. These can cut more complex designs for brands like Oakley or Maui Jim, including step-back bevels, inclined bevels, drill mounts for rimless frames, gem settings and even decorative faceting.

This flexibility means we can handle everything from everyday lenses to custom, high-performance or decorative designs.

Ensuring the Perfect Fit

As each lens is edged, we check it against the frame for size, alignment and pressure. A proper fit ensures the lenses sit securely without being too tight - avoiding issues like fractures or stress points that could show up months later.

With edging complete, the lenses are now shaped to the frames and ready for the next step: tinting.