How Lenses Are Made - Part 7

Thin Film Coating

The final step in lens processing is adding a thin-film anti-reflective coating. This invisible layer can reduce glare, improve clarity and enhance comfort.

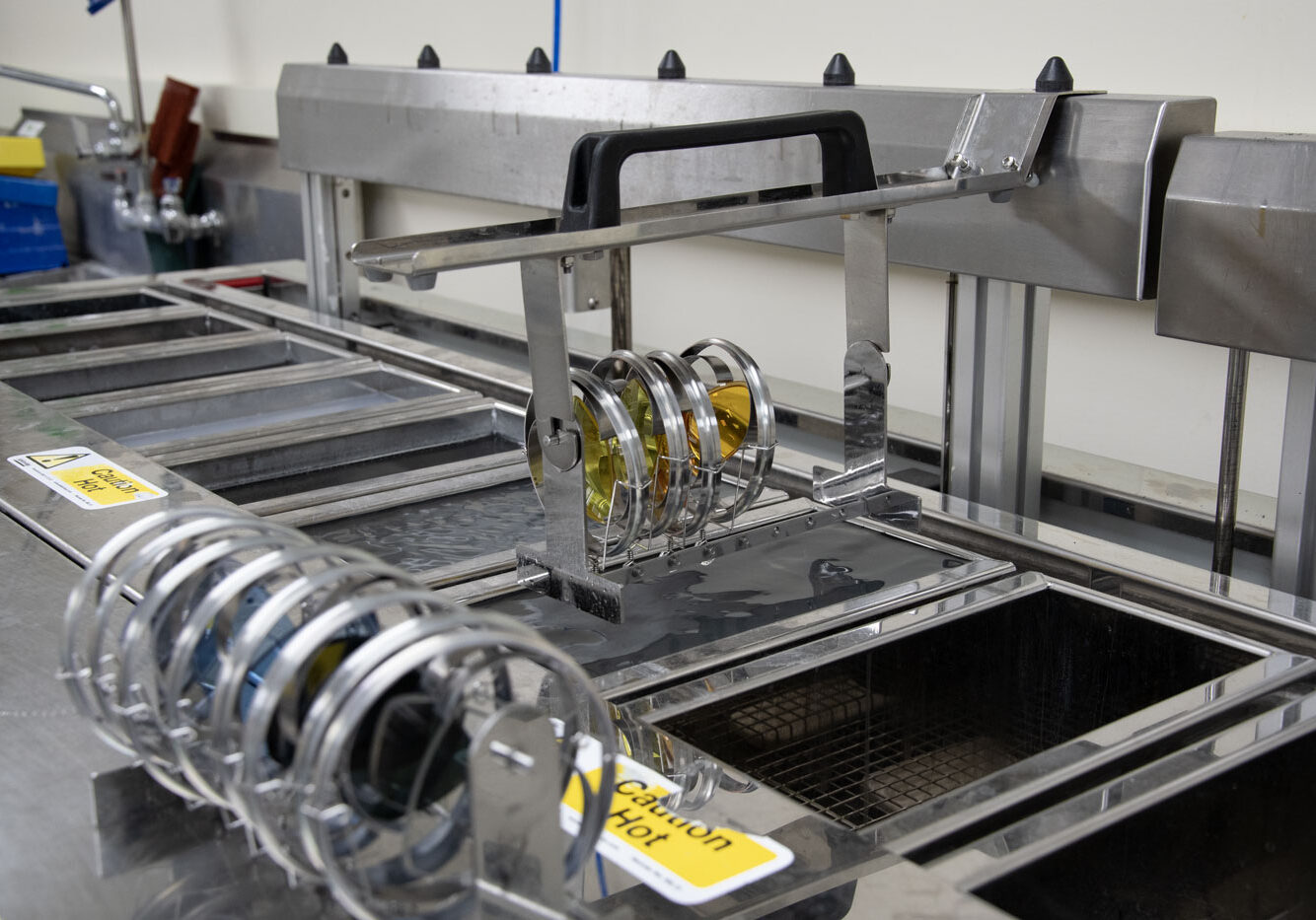

Step 1: Cleaning and Preparation

The lenses are placed into ring holders, which secure them for processing. They are then immersed in a series of soap baths to remove every trace of dust, dirt and oil. Any debris could cause defects once the coating is applied.

After cleaning, lenses go into an oven for several hours. This evaporates any remaining moisture inside or on the surface of the lens, preventing imperfections in the final AR layer.

Step 2: AR Deposition

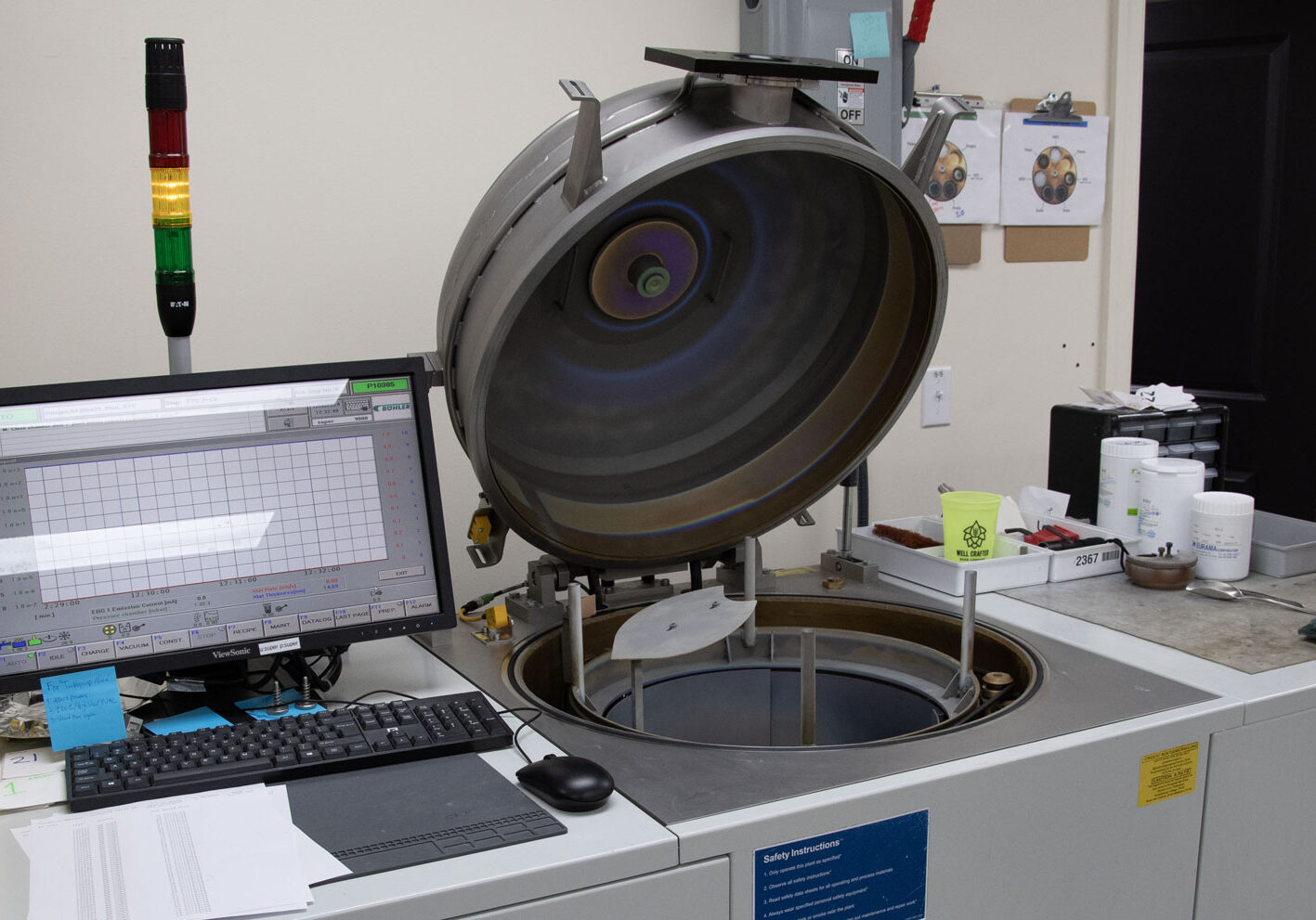

Once prepped, the lenses are ready for the AR machines.

Here’s how the AR layer is formed:

- Lenses are placed in the machine along with a crucible containing special coating chemicals.

- A high-energy electrical charge (like a lightning bolt) heats the crucible, vaporizing the chemicals.

- The vapor condenses on the lenses, forming precise, ultra-thin layers that create the AR effect.

- Depending on the recipe, this process is repeated to build multiple layers for premium coatings.

For backside-only AR, the front of the lens is covered to protect it from deposition.

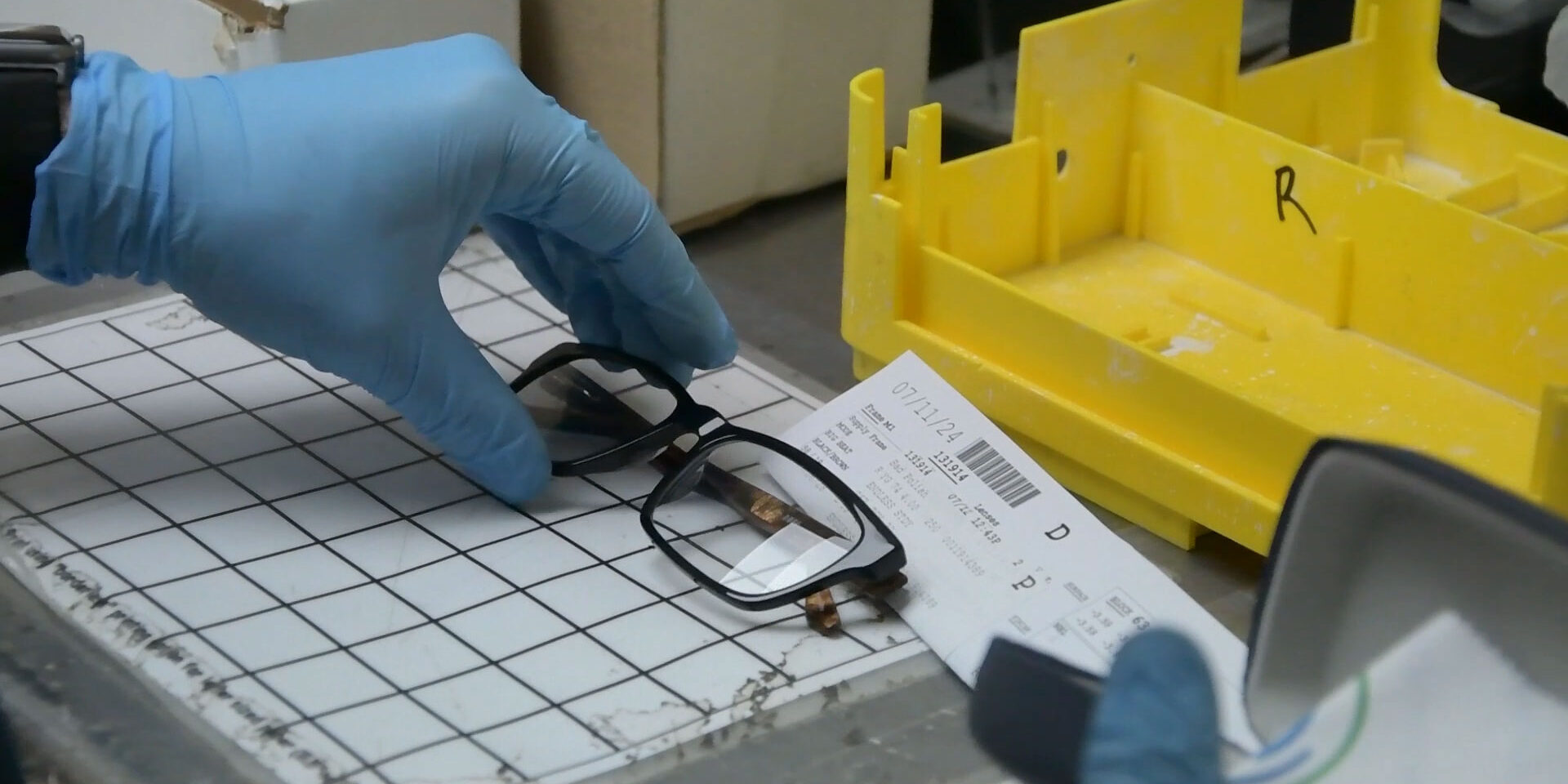

Step 3: Final Checks and Assembly

After coating, lenses are removed from the rings, inspected for clarity and defects, and returned to their trays. They then move to final assembly, where they are:

- Mounted into their frames

- Verified for prescription accuracy and alignment

- Quality-checked one last time to ensure a flawless finish

Once complete, the lenses are ready for shipment.