How Lenses Are Made

From creating the molds to make lens blanks to applying AR coating to prescription lenses, this guide walks you through the entire process of lens making.

Creating Lens Blanks

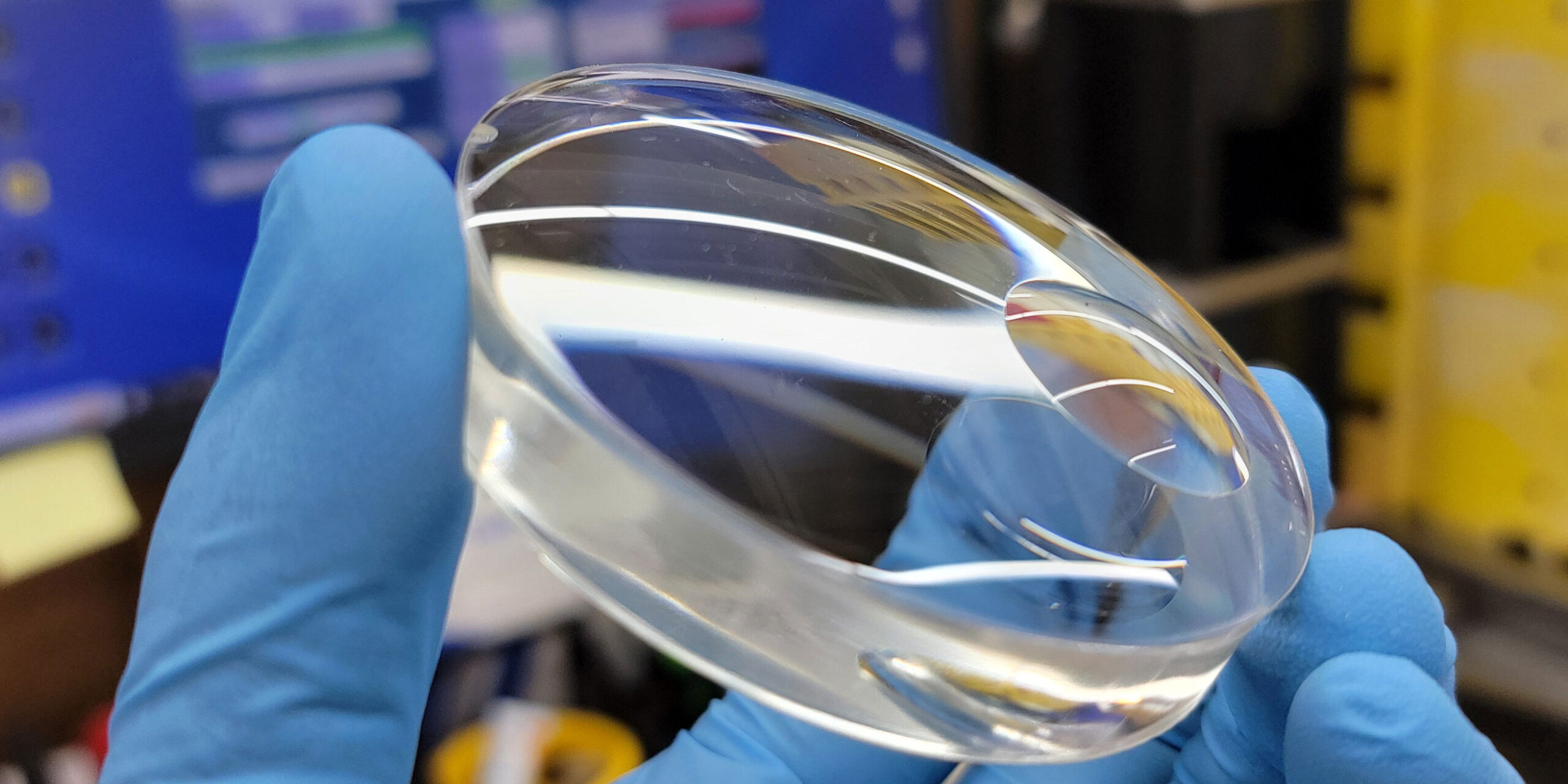

Lens Processing

In the surfacing department, the lens blank is cut to the exact prescription. Machines carve the back of the lens to create the sphere, cylinder and any progressive curves needed. Polishing smooths out the surface, and soft or hard tools bring the lens to crystal-clear clarity. This step transforms the blank into a prescription lens.

Tinting adds color and protection. Lenses are dipped into heated dye baths where the coating and lens material absorb the color. For complex tints, multiple dyes are blended to match exact shades. Every lens is checked under different lighting to ensure consistent color and proper light transmission.