High Minus

Is your patient’s nearsightedness off the charts? Thankfully, the traditional Coke bottle glasses are a thing of the past, thanks to custom optics and high-index lenses.

But how much thinner is high index than a regular lens, you ask?

When determining the thickness of a lens, there are two curves to consider: a front curve and a back curve. By using a high index, you’re able to use a flatter back curve to accomplish the same high minus power. This thins out the edges of the lens. An easy way to estimate how much thinner a certain lens will be in a different index is by dividing their indices of refraction. The reason this is an estimate is it doesn’t account for asphericity or the fact that certain materials can be ground to a thinner center than others.

How thin is 1.74 compared to CR-39 (1.498)? (1.498 – 1) / (1.74 – 1) = 67.3% of the thickness of CR-39.

You can use the above formula to compare any two materials. Or you can use this chart:

| Trivex | 1.60/ Poly |

1.67 | 1.70 | 1.74 | |

| CR | 6% | 17% | 25% | 30% | 32% |

| Trivex | 11% | 20% | 24% | 28% | |

| 1.60/Poly | 10% | 14% | 19% | ||

| 1.67 | 4% | 9% | |||

| 1.70 | 5% |

If you have a patient with a -20.00, using a 1.74 index lens reduces the edge thickness to roughly the same thickness as a -14.00 CR-39 lens. That thickness is often not satisfactory to a discriminating patient. To help make these lenses look better, we offer a number of different lens shapes that you can choose from to improve the appearance of a high minus RX.

Standard Shapes

The standard shapes, #1 & 2, are surfaced in the normal way, and we do not run the lens through any additional processes to thin out the edges. While these shapes are the most affordable, they can also be quite unsightly in high RXs if you’re not using an appropriate frame.

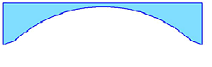

Shape #1: Standard

Flat or convex front curve, standard back curve with no effort to mitigate edge thickness.

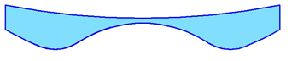

Shape #2: Biconcave

Concave front curve, standard back curve with no effort to mitigate edge thickness. Used when the RX exceeds machine curve limitations for shape #1.

Shape #9: Freeform HD Wrap

This lens design is used for unusual base curve requests. For instance, a -7.00 in an 8 base wrap frame.

Myodisc Shapes

Myodiscs are surfaced on the backside using 2 different curves. The back curve in the center, and then an alternate curve to thin the edges of the lens.

Shape #3: Standard Myodisc

Flat or convex front curve, with a concave bowl cut into the center of the lens. The rest of the lens is cut on a convex curve to drastically reduce edge thickness. The typical bowl size is approximately 40 mm.

Shape #7: Back Fade

Where the myodisc cuts a convex curve on the back of the lens, the back fade cuts a flatter concave curve on the back of the lens. This thins the lens, but not as drastically as the myodisc.

Blended Myodisc Shapes

Blended Myodiscs are surfaced on the backside using multiple different curves. The back curve is cut in in the center, and then a series of curves are cut to blend the bowl’s transition into the edge of the lens.

Shape #4: Blended Myodisc

Processed much like a traditional myodisc, but with an additional finishing process to blend the bowl to the rest of the lens.

Shape #5: Biconcave Blended Myodisc

Used when the RX exceeds machine limitations on Shape 4. A concave curve is cut into the front of the lens to make a lens with more power.

Shape #6: Biconcave Double-Blended Myodisc

Used to further thin a Shape 5 lens. The lens is run through the blending process on both the front and the back of the lens.